NEWS

NEWS

What are the material choices for high-speed optical module heat dissipation?

The optical module is composed of optoelectronic devices, functional circuits and optical interfaces, etc. The optoelectronic device includes two parts: transmitting and receiving. The function of the optical module is photoelectric conversion. The transmitting end converts the electrical signal into an optical signal. After transmission through the optical fiber, the receiving end converts the optical signal into an electrical signal.

With the 5G network construction, AR / VR interactive experience, 8K ultra-high-definition video transmission, cloud computing, Internet of Things, Internet of Vehicles, AI and other technologies have continuously made breakthroughs and developments, and global data traffic has continued to rise. Data centers have moved from 100G to the development of higher transmission, higher response rate, higher frequency bandwidth and lower delay, 400G Ethernet shows an inevitable trend of becoming a data center. As the core device that carries network traffic, the demand for optical modules will continue to be driven.

As a midstream product, there are optical and electrical core chips in the optical module industry, and there are large customers such as cloud manufacturers or telecommunications equipment vendors. The pressure on the cost side is high, the technology update iteration is fast, and the outstanding quality and performance can stand out.

The heat source of the optical module is mainly located near the PCB chip and the optical devices (TOSA and ROSA). The main difficulty of the motherboard chip heat dissipation is that when the mother board or the single board, the component with large heat generation is located on the bottom, the heat generated by the chip cannot be transferred to the main unit. To solve the heat dissipation problem of the optical module, the heat dissipation panel must meet the two conditions of heat conduction and heat dissipation. The heat dissipation of chip components mainly uses high thermal conductive materials with a certain degree of flexibility.

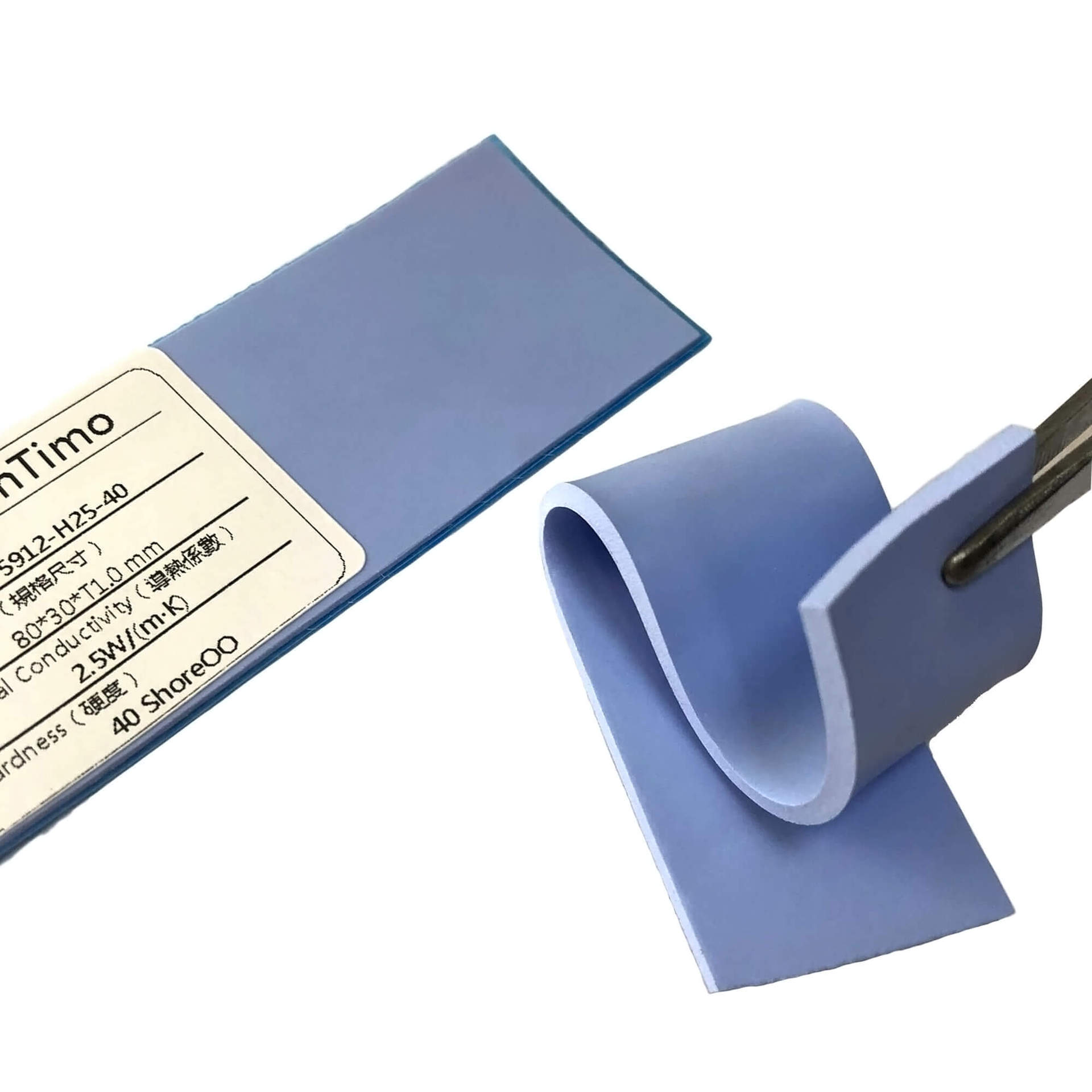

Waermtimo developed the new TIM WT5912-H25-40 high-strength thermal conductive pad, which is a thermally conductive sheet with high mechanical strength. The elongation rate is over 300%. It has high toughness and thermal conduction. It can effectively absorb shock, at the same time, repeat heavy work and continuous folding, can closely integrate irregular or complex surfaces, has excellent interface filling and can be used repeatedly. Thermal conductivity is 2.5w, temperature range -50 ~ 200 ℃, a wide range of applications, power supply equipment, automotive electronics, communications equipment, network terminals, storage devices, handheld, wearable, mobile terminal products and internal chips and between the radiators, this type of pad can be used to solve the problem of heat conduction and heat dissipation. It can also be applied to the housings of some electronic products to make it have the functions of heat dissipation, insulation, dustproof and waterproof.

WT 5902-D45 thermal pad can solve the problem of product structure design tolerance changes and can be reused. It is a excellent vertical thermal conduction material between the heat source (CPU or electronic chipset) and the heat sink. With excellent insulation and mechanical properties, it can closely integrate irregular or complex surfaces, easy to use and remove. The thermal conductivity of the thermal pad is 4 ~ 6w, which is widely used in power supply equipment, automotive electronics, communication equipment, network terminals, storage devices, consumer electronics and other fields.

In 2020, optical modules are also one of the few industries that are not affected by the epidemic but benefit from the new infrastructure policy, and are ushering in their own highlight moments.

For more information, pls contact:

Email: [email protected]